DCS & AUTOMATION EXPERIENCE

PSE has a wealth of experience working in controls and automation. PSE has been designing and commissioning Programmable Logic Controllers (PLC) and Distributed Control Systems (DCS) for over 20 years. Our real-world DCS experience provides an extra dimension of support for our customers as our engineers have factory training coupled with years of experience in commissioning DCS systems that differentiates us from others with only factory training. We have engineers who have experience with the following

DCS

- Rockwell Automation PlantPAx

- Siemens PCS7

- Emerson DeltaV

- Emerson Ovation

- Foxboro

- Moore APACS and QUADLOG

- Honeywell TDC 3000

Over the years, we have completed DCS projects for a variety of customers in mining, oil, and gas. More detailed information about our qualifications is available upon request.

PLC & AUTOMATION EXPERIENCE

PSE has a great deal of experience working with programmable controller-based (PLC) control systems and the human machine interface (HMI) software normally included with a PLC system. We have engineers who have been trained on the following PLC and HMI systems:

PLCS

- Allen-Bradley – PLC5, SLC500, MicroLogix, Micro850, CompactLogix, & ControlLogix

- Siemens – S7 Series

- Modicon – 484, 984, Micro, & Quantum

- Square D – Symax 300, 400, 500, & 700

- General Electric Series 6, 90-70, 90-30, Genius

We have completed PLC-based automation and controls projects for a variety of customers in a number of different industries.

Note: On June 1, 2016, after more than 30 years of life, Rockwell Automation announced the discontinuation of the Allen-Bradley PLC-5 control platform in June 2017 and will no longer be available for sale. Contact PSE to plan your migration to a new PLC platform today.

HMI

- Rockwell Software: FactoryTalk, RSView32, and PanelView

- Wonderware System Platform: Archestra, InTouch

- GE Proficy: iFix

- Siemens: TIA Portal, WinCC, WinCC Flex and Factory Link

Historian

- OSIsoft PI System

- FactoryTalk Historian

- Wonderware Historian

- Siemens

PROCESS AUTOMATION EXPERIENCE

From the hundreds of projects completed over the years, PSE has developed extensive knowledge of processes such as:

- Regulatory

- Batching systems

- Routing control

- Equipment sequencing and interlocking

- Particle size reduction

- Agglomeration and pelleting

- Cooling and drying

- Fluidized bed controls

- Coating systems

- Kiln & Roaster control

- Paper milling processes

- Hydraulic systems

- Electron-beam furnaces

- Utility controls

- Power generation controls

- Mining /Ore processes

- Liquid handling & control systems

- Automated machine control

- Safety-integrated control systems

- Failsafe Systems

- Redundancy

PANEL FABRICATION

Unlike most engineering firms, PSE also has our own panel fabrication shop in our Sandy office. This shop is equipped with all the facilities required to build any panels needed by our clients. PSE is registered with Underwriters Laboratories (UL) as a UL508A industrial control panel builder (UL category NITW). All control panels built by PSE comply with the UL508A standard to ensure safety and quality.

Having the company that designed your control system also build and test the system ensures that your control system performs as designed and manages your plant operations with maximum efficiency. PSE can perform Factory Acceptance Testing (FAT) at our facility.

OTHER SERVICES

PSE can also provide systems that include stepper motors, servo motors, and robots. Specifically, PSE has experience with Parker servo motors and drives, AMC stepper motors and drives, and collaborative robots from Universal Robots.

These things combined with our automation experience with PLCs, HMIs, and panel building, PSE can provide machine controls, work cells, process, and plant-level systems to process or manufacture your products.

PANEL CLEANUP

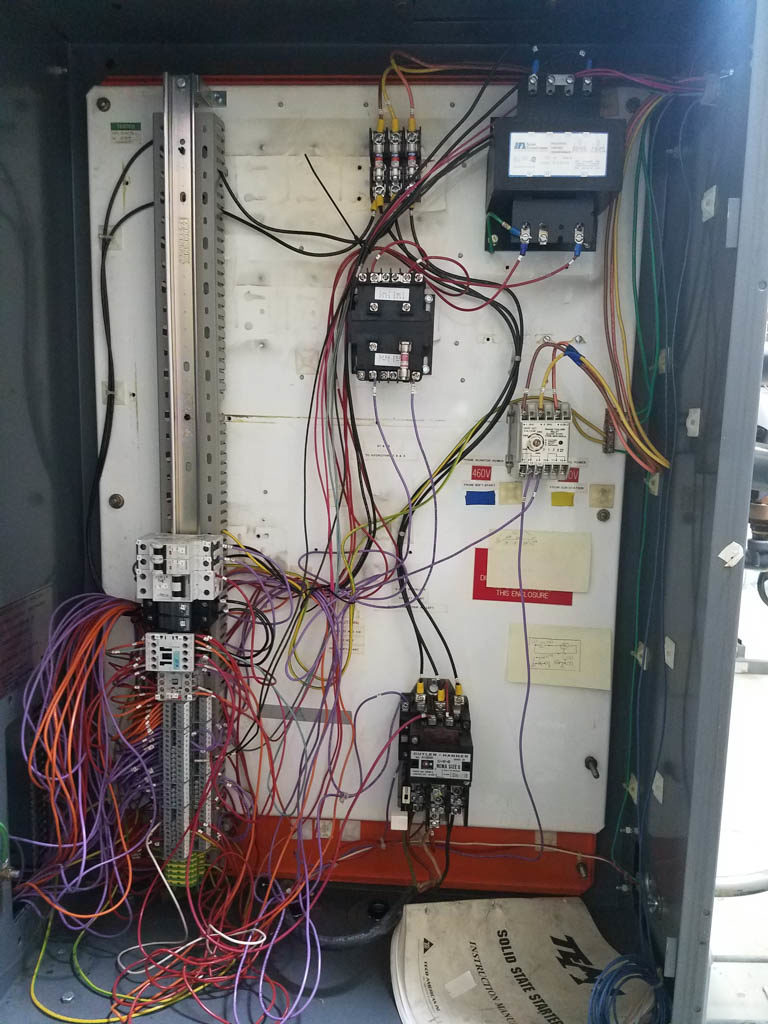

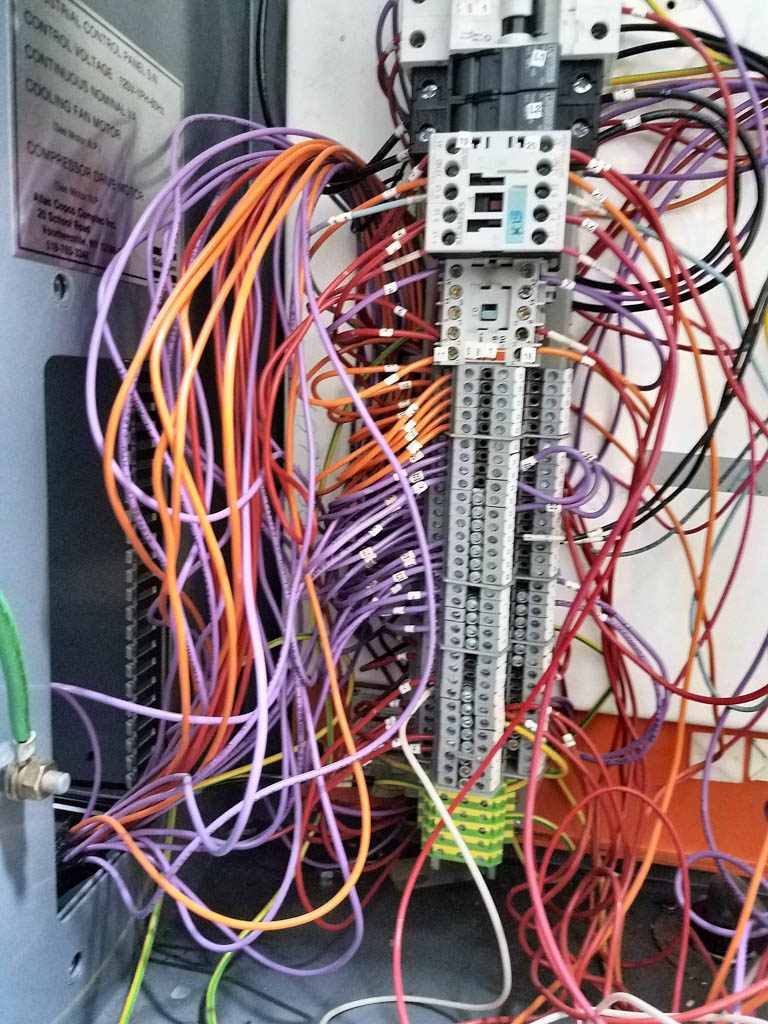

- A cluttered PLC panel.

- Cluttered PLC panel 2

Do any of your control panels look like this?

- No documentation

- Difficult to troubleshoot

- Unsafe

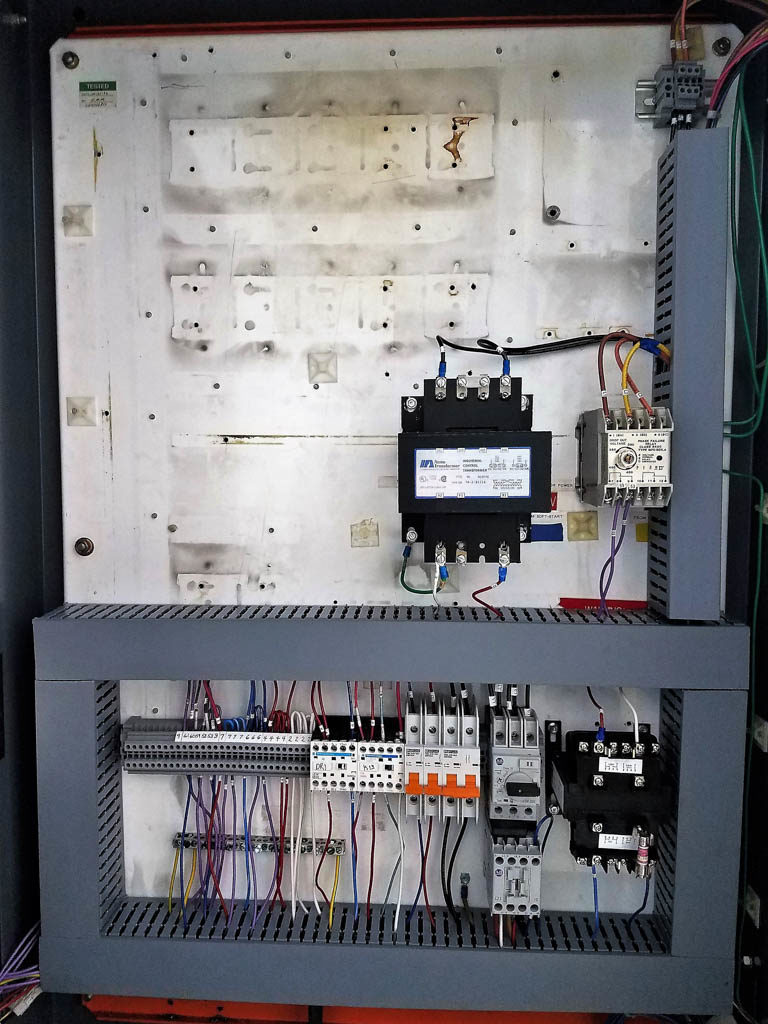

- PSE Updated panel

PSE solved it in one day!

- New drawings

- Wires labeled and organized

- New components as required